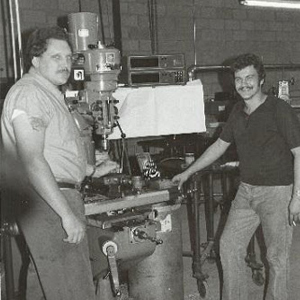

Supplying customers with high quality precision & custom metal stampings since 1978.

Since 1978, Ronlen has been all about metal stampings. Manufacturing expertise, from a wide range of extraordinary materials. We assist customers throughout design, development, prototyping, production, post processing, and shipping. We improve product engineering while simplifying production, reducing cost and delivering on time.

Our Engineering team offers expertise in Prototypes, Tool & Die design, Metal Stampings and much more.

Providing efficient and cost effective solution for all your custom, precision stamping needs.

Our in -house toolroom allows us to reduce down time for production and keep all new tool build functions in house for greater control and flexibility.

From concept to end of life, Ronlen is your source to efficiently handle your stamping project needs.

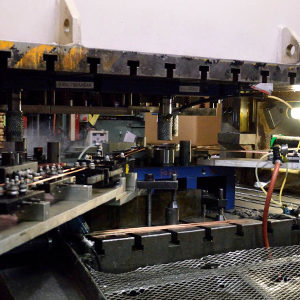

Ronlen’s precision metal stampings are manufactured on dies engineered and produced in house to meet our customers’ material, application and volume requirements. We ensure accuracy, availability, low costs and superior product quality. Our services include:

We’re efficient, cost-effective, precise. We’ll accommodate all of your production requirements with quality tooling designed and built in-house.

We build the best progressive dies and assembly tooling in our in-house shop. We reduce downtime and shorten delivery times through planned die-change methods, routine die maintenance and well-maintained equipment.

Establishing a high standard of quality control in the preliminary phases of a project is critical. Our engineering staff will guide you through the design of new parts, and modification of existing parts.

We utilize multiple CAD & CAM (Computer Aided and Manufacturing) platforms in the preliminary stages of production, and collaborate with you on your designs to produce best-on-the-planet stamping.

Welding, Tapping, Plating, Heat Treating, Powder Coating, Metal Finishing, Assembly, Deburring, & Machining.

We can help manage your largest production runs, and assist throughout all phases of design, development, prototyping, post processing and delivery.

The breadth of industries we serve has certainly expanded over the years: Automotive and electrical equipment, for high-tech brake applications, with the level of expertise and attention to detail for every one of our customers across a variety of industries.

mwolf@ronlen.com (330) 273 6468